Column micrometer

In the field of mechanical production, assembly and control, column micrometers

of the A&V 4000 series proved their worth in many applications. They are for example

used to measure lenghts of down to 1/1000mm and work in combination with manually

operated measuring devices and up to fully automatic measuring stations.

The measuring values are clearly displayed and the tolerances are monitored.

There are interfaces to the machine control and to quality management systems.

Due to their wide application range from single measuring tasks to complex

multi-unit measurement stations with programmable measuring value linkages and

analyses, these units are ideally applicable. Their easy handling, the clear

measuring value display and the tolerance control facilitate a quick familiarisation

and lead to a complete acceptance with the user.

For the measuring value recording we use:

- inductive transducers

- strain gauge pressure transducers

- potentiometric sensors

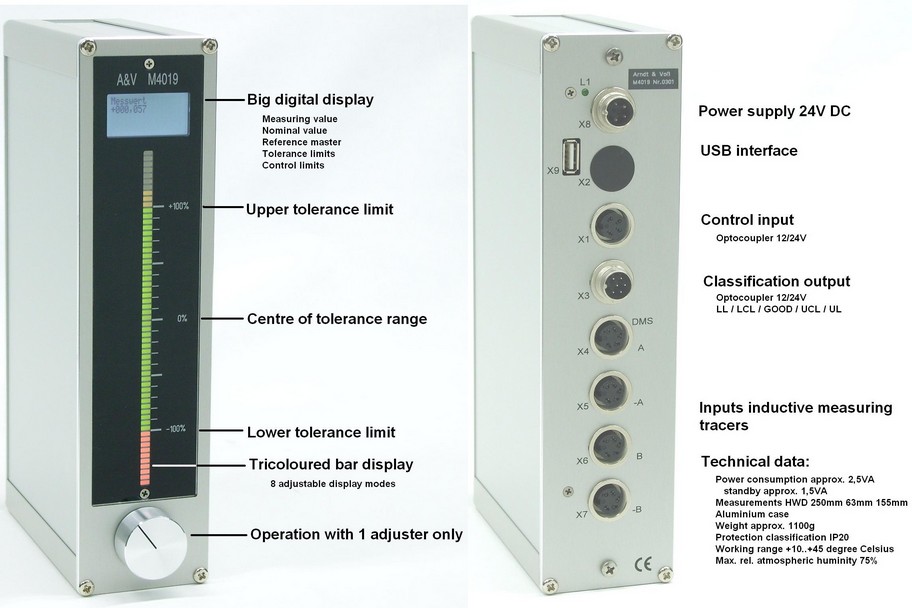

A&V M4019

A&V 4019 is equipped with four tracer inputs +/-A, +/-B.

A&V M4019 -4044

Maximum and minimum storage makes it possible to measure dynamic measurement cycles.

A&V M4019 -4045/4307/4763

Equipped with zero point memory which highly simplifies the adjustment with the master. The working range of the zero point memory is at 60% of the maximum measuring range.

The essential characteristics of the column micrometers are:

- brilliant analogue tricoloured luminous row measuring value display with

tolerance mark

- digital number display

- tolerance classification in 5 classes

The comprehensive model portfolio basically covers all occuring requirements,

like for example:

- Individual, sum or differential measurements

- Automatic zero point adjustment; zero points are set with a key or

an external signal; with separate signals, zero points are set

individually

- Digital memory for dynamic measurements like concentricity, max. pressing

force, average torque etc.

The actual scale may be compensated automatically. Thus, it is possible to

stably measure dynamic max-min measurings in high-definition ranges (e.g. 0.5 mm)

for high work piece tolerances (e.g. 0.5 mm).

Technical features of the electronic measuring equipment:

The electronic measuring equipment completely meets the requirements of

precision metrology. There are no bad compromises but an ideal technology and

an optimal price/performance relation.

The measuring sensors are supplied through a special transformer. This

results in the best symmetry and efficiency. There is no DC voltage portion

at the measuring sensor.

The input amplifier is designed as AC voltage amplifier with approximately

100-fold amplification. The temperature drift of the electronic measuring

equipment is thus 10 times better than with measuring sensors supplied with

DC voltage. The demodulator receives a high signal. This improves linearity.

A real phase-controlled demodulator inhibits extrinsic interfering voltages

of the measuring signal.

All measuring resistors have a small temperature coefficient (25ppm) and

a low tolerance (0.1%).

The temperature drift of the electronics between 10 and 60 degrees Celsius

is better 0.2% (except for mechanics and measuring transducers).

A comprehensive quality control during the production and the following

long-time test ensure an outstanding reliability of the units.